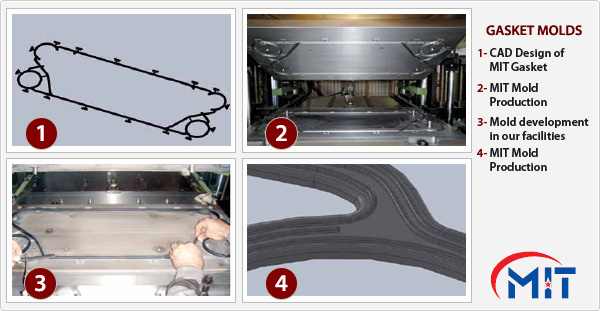

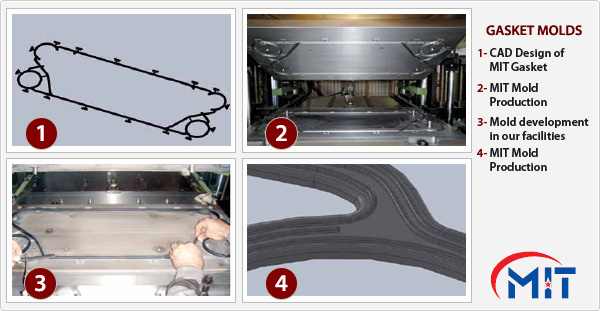

Gasket Molds

The quality of MIT Gaskets is the result of newgeneration production molds.

- CAD/CAM Center

- Two CNC units

- Mold device

- Lathe line

- Mold maintenance line

Due to these possibilities, we are able to render a new mold ready for production in 30 days.

In our facilities, mold development is conducted as follows:

- There is a serial production line

managed with a timeline which

saves shipping costs throughout

the transportation process.

- Suitable gasket prototypes are

tested before the production

and the final product is

guaranteed.

- While the gasket profiles are

developed, it is possible to make

changes within a short period

of time.

EXCHANGER GASKET

information

Plate Heat Exchanger Technology

MIT Plate Heat Exchangers, the rising star of Plate Heat Exchanger market, takes heart from the design team which gives continuous support.

read more..

Plate Types

These plates are used in standart applications such as, supplying hot utility water, low pressure steam applications and site heating.

read more..